Advancements in Design and Materials

Wood floor trusses have undergone rapid evolution due to advancements in technology and materials. Software tools like CAD and BIM enable architects, engineers, and builders to optimize truss designs collaboratively before construction begins. These digital platforms minimize waste, maximize load-carrying efficiency, and tailor each structure to its specific application. This accuracy results in stronger, more reliable flooring systems, reduced surplus material, and improved budget and environmental impact. For construction projects in California seeking to lead in both quality and innovation, it’s wise to partner with local providers specializing in wood floor trusses California. Suppliers are utilizing advanced design technologies and top-tier engineered components to meet industry standards and regional building codes. Engineered wood products, such as cross-laminated timber (CLT) and glued laminated timber (glulam), are expanding the possibilities for architectural design. These products offer superior strength-to-weight ratios, longer spans, and open-concept layouts. They are also sustainable, using responsibly managed forests and producing lower embodied carbon. This shift in the construction industry enables the creation of greener buildings without compromising performance, aesthetics, or safety.

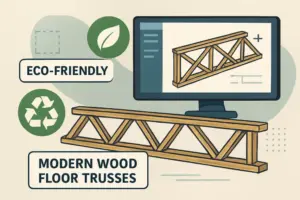

Sustainability Trends in Floor Trusses

Wood floor trusses are gaining popularity as a sustainable alternative to traditional construction materials. Manufacturers are incorporating recycled or reclaimed materials into their products, reducing waste and resource demand. This aligns with green building certifications, such as LEED, and meets consumer expectations for responsible building materials. Engineered wood products sequester carbon, offsetting other greenhouse gas emissions during construction. Advanced floor truss systems provide long-term value to clients and communities, and builders who champion these innovations differentiate their offerings in an eco-conscious market.

Cost Efficiency and Installation Benefits

Cost efficiency in building projects is crucial, considering not only raw material prices but also the entire lifecycle cost. Strategic choices in floor truss systems can unlock savings across various phases, from material procurement to long-term operation. A Midwest home builder found direct savings of over $800 per home by transitioning from traditional 18-inch trusses to slimmer, engineered 11.875-inch I-joists. Prefabrication is another game-changer, streamlining the construction process by designing, cutting, and labeling the entire system in the manufacturer’s facility. This results in faster project completion times, fewer delays, and greater client satisfaction, solidifying prefabricated trusses as a go-to choice for builders nationwide.

Technological Integration and Automation

The integration of robotics and automated systems in truss manufacturing plants has significantly improved speed, efficiency, and product consistency. Automated CNC cutting and robotic assembly eliminate errors associated with handcrafted work, thereby boosting production capacity and reducing turnaround times. This shift ensures superior quality and uniformity in every batch. Digital tools, such as CAD and BIM, enhance industry collaboration, allowing stakeholders to visualize and refine projects simultaneously, thereby reducing miscommunication and delays. This professionalization is setting new standards for efficiency, transparency, and project accountability.